Precious Metal Recovery, Reclaiming, and Recycling for Complex Industrial Streams

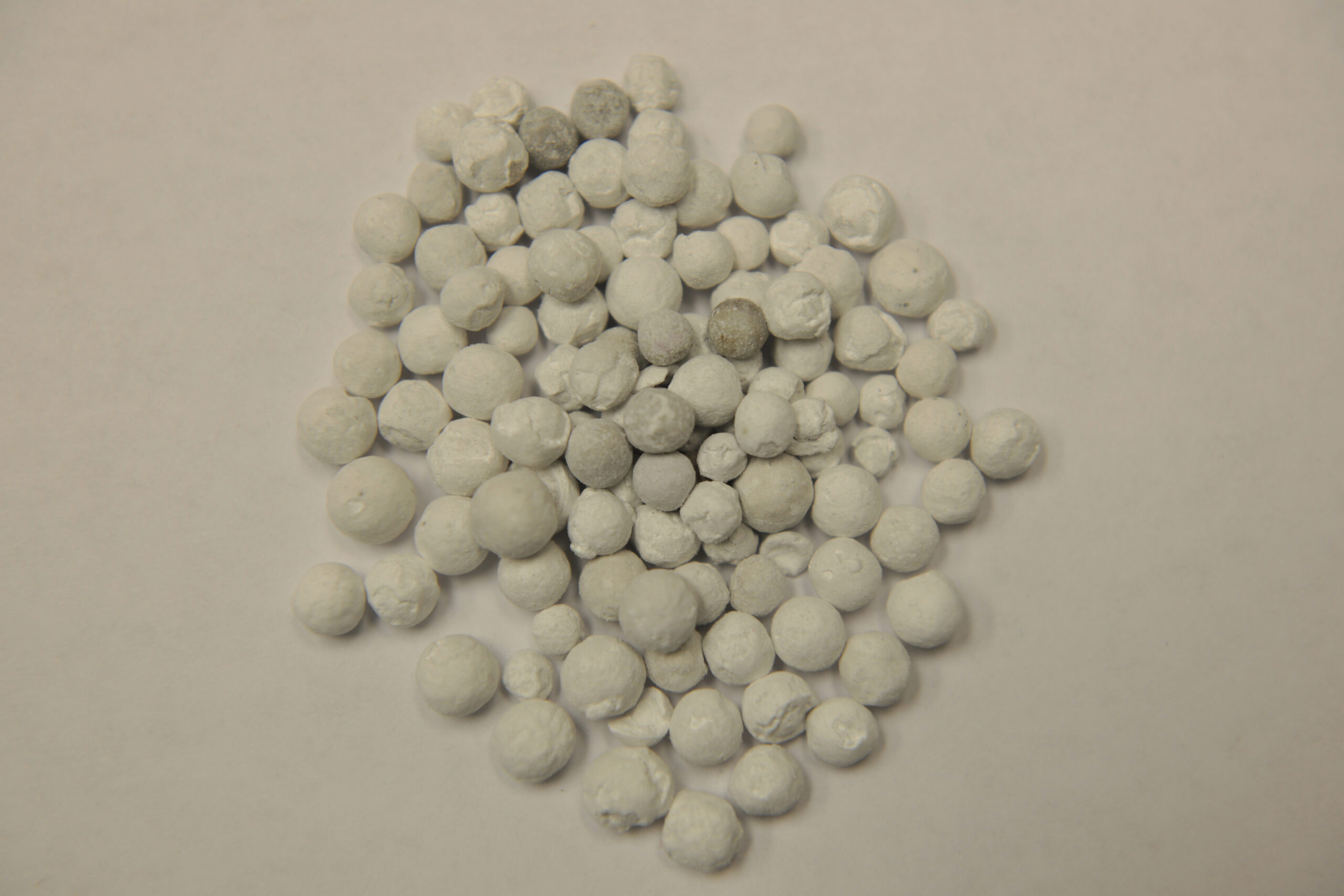

Every industrial process produces residues that contain untapped value. Spent catalysts, metallic scrap, and complex sludges often carry significant concentrations of precious metals. But without the right partner, those resources remain locked away. That’s where we can help.

Metal & Catalyst Resources provides precise, accountable precious metal recovery services to maximize yield and minimize risk. Through advanced processing, transparent sampling, and proven refining partnerships, each lot is treated as a high-value asset. With decades of expertise across platinum group metals, gold, silver, and rhenium, we help industry turn waste into accountable value.

If you have waste or off-spec material containing precious metals and want to explore recycling options, the team at Metal & Catalyst Resources is ready to help.

Start Your Precious Metal Recycling Project with Metal & Catalyst Resources

If you have spent, waste, scrap, residual, or off-spec material containing precious metals or precious metal compounds, the opportunity to recover value is too important to overlook.

Metal & Catalyst Resources provides the expertise, infrastructure, and transparency needed to turn complex streams into measurable returns. Whether you are ready to recycle material today or would like to discuss the specific characteristics of your feedstock with our technical staff, we invite you to get in touch and explore how our precious metal recycling services can support your operation.

Frequently Asked Questions About Precious Metal Recovery, Reclaiming, and Recycling

When evaluating precious metal recovery or recycling options, technical details and process clarity are often just as important as yield. To help address common considerations, we’ve compiled answers to frequently asked questions about our precious metal reclaiming and recycling services.

Yes. Mixed materials containing multiple precious metals can be processed, with recovery paths designed to separate and account for each element individually. This ensures accurate yield and settlement for all contained values.

Turnaround depends on the material type, the precious metals involved, and the processing route, and most cycles are measured in weeks or months. Customers receive updates and reports throughout the process.

Precious metal recycling services can be arranged for both small trial lots and large-scale shipments. Each batch is profiled to ensure the process route is efficient and cost-effective at the given scale.